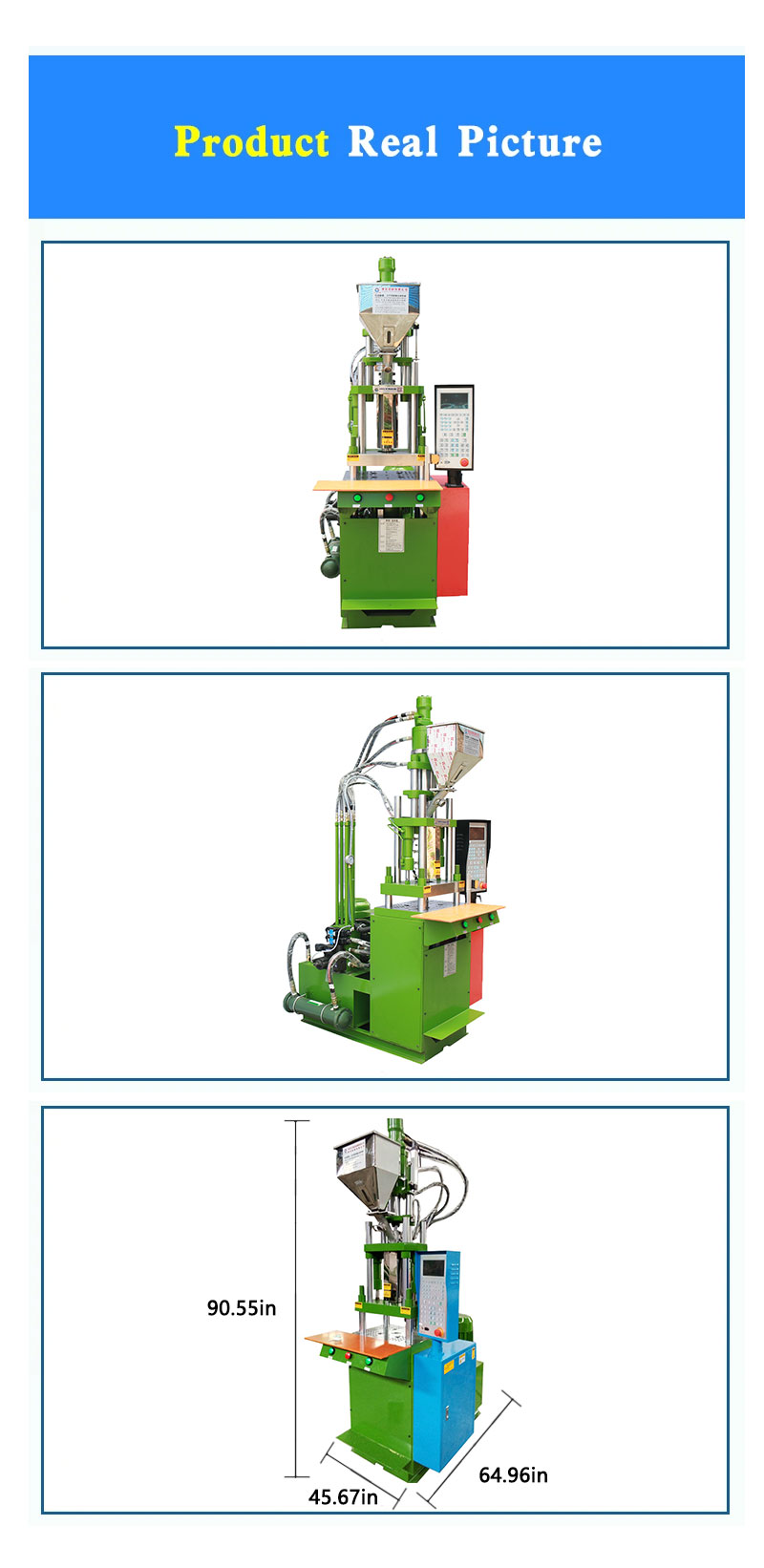

JY-450ST Vertical Plastic Injection Molding Machine

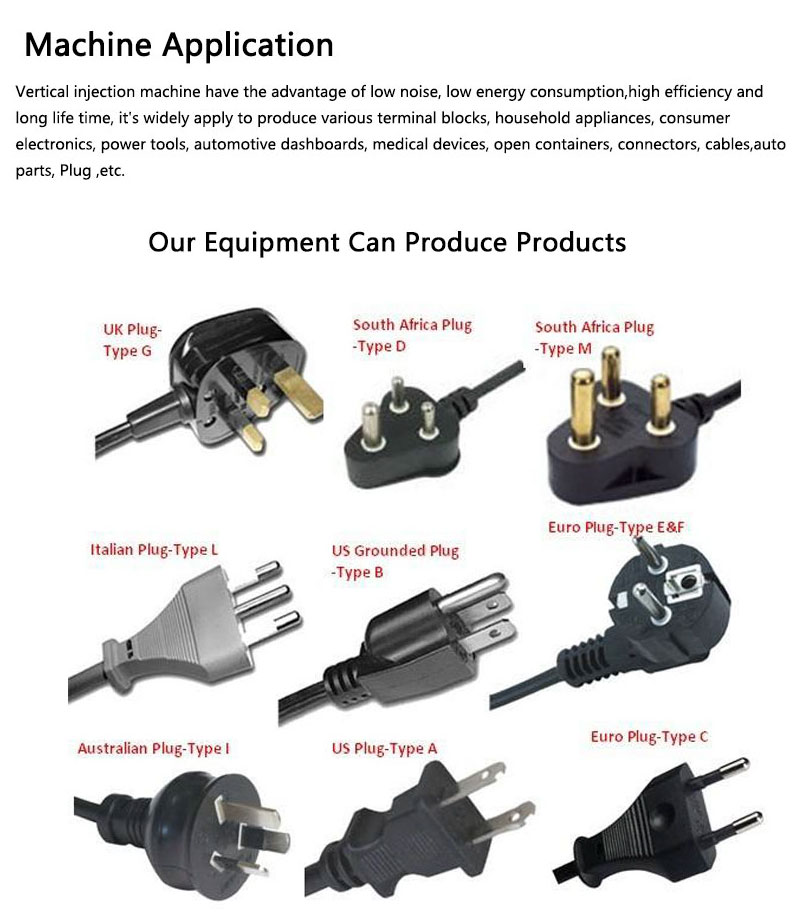

High-Strength, High-Precision Plug Molding Solution for Demanding Industrial Applications

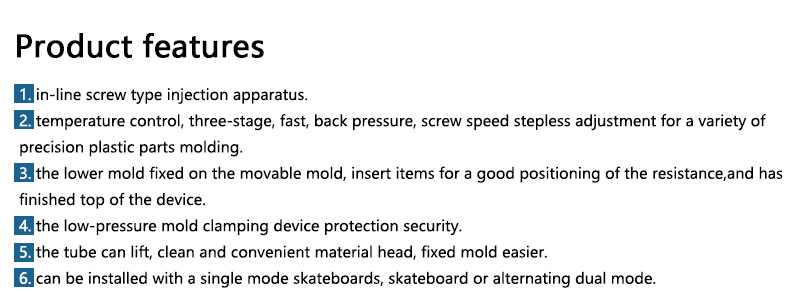

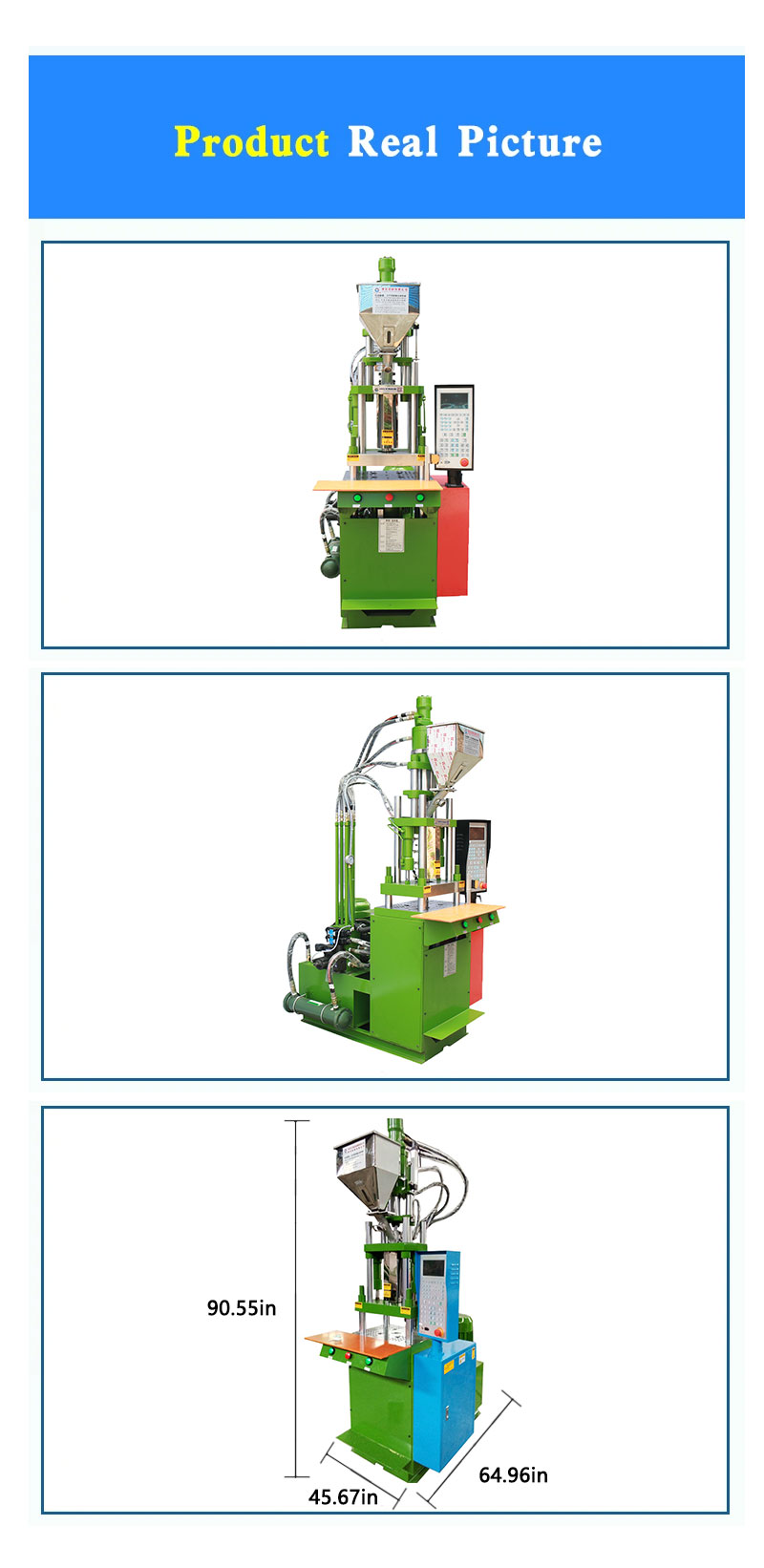

The JY-450ST Vertical Injection Molding Machine is engineered for manufacturers seeking exceptional precision, stability, and flexibility in plug molding and insert molding applications. Built for complex and high-volume production environments, this model delivers reliable performance through its advanced plasticizing system, enhanced mold support structure, and smooth parameter control.

Designed to meet the evolving needs of electronics, electrical components, automotive accessories, and precision consumer products, the JY-450ST provides a strong combination of molding accuracy, operation convenience, and long-term mechanical durability.

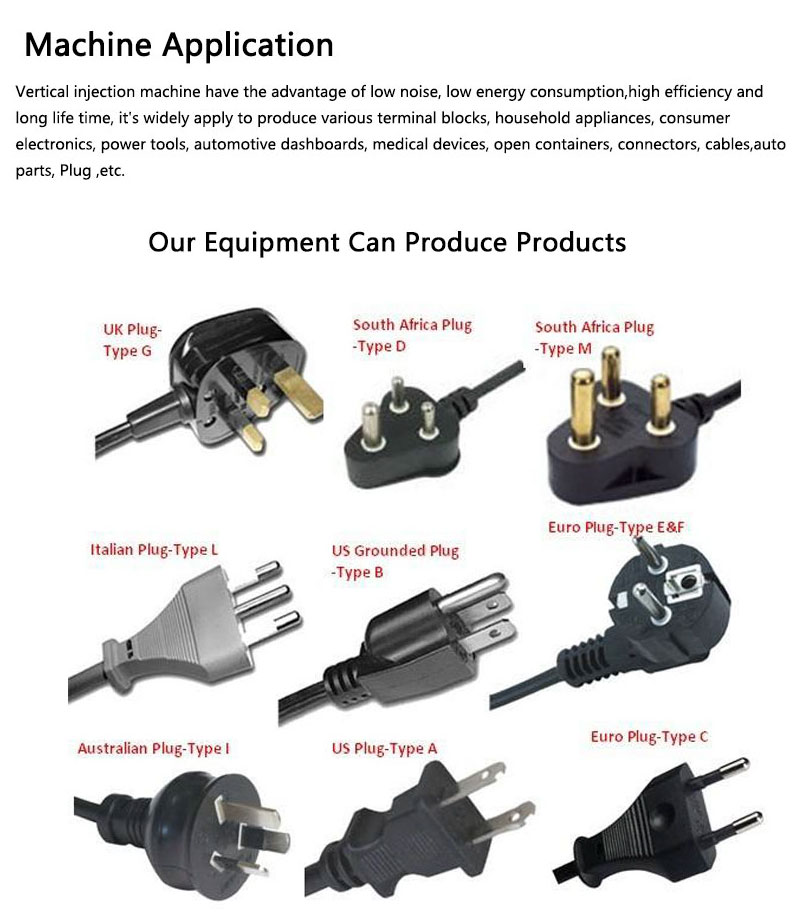

Structural Strength & High-Performance Injection System

The JY-450ST incorporates a robust injection framework capable of maintaining consistent clamping and injection force during long-term, continuous operation. Its enhanced mechanical rigidity ensures minimal deformation during high-pressure molding cycles, making it especially suitable for plug-type products that require uniform filling and dimensional stability.

The injection unit delivers stable melt flow, allowing operators to mold products with narrow tolerances and complex geometries. This performance stability is essential for manufacturers prioritizing product precision and repeatability.

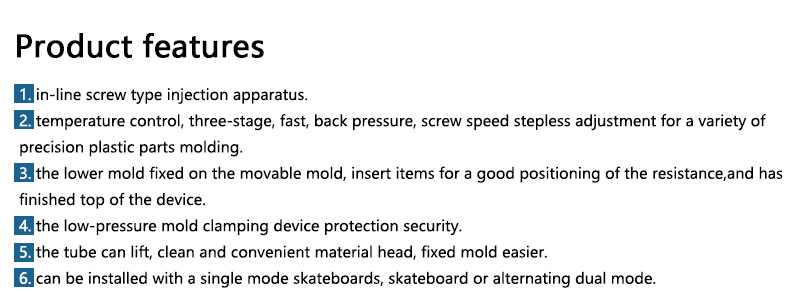

Enhanced Precision for Complex Plastic Parts

With its advanced injection control design, the JY-450ST supports precise adjustments of injection flow, molding pressure, molding temperature, and plasticizing speed. These capabilities allow manufacturers to fine-tune the molding process to match the requirements of different plastic materials, including engineering plastics and high-temperature compounds.

Whether producing micro-sized components or larger molded plugs, the machine ensures consistent wall thickness, accurate product dimensions, and smooth surface finishes.

Optimized for Insert Molding & Stable Positioning

The JY-450ST is optimized for insert molding tasks where precision alignment and stable part positioning are critical. Its vertical clamping structure offers a natural advantage for placing metal inserts, terminals, or embedded components manually or via automated systems.

The machine's mold design allows inserts to settle accurately into position throughout the molding process, reducing the risk of shifting, deformation, or product defects. Manufacturers benefit from improved yield rates, shorter cycle times, and greater operational reliability.

User-Friendly Operation & Easy Maintenance

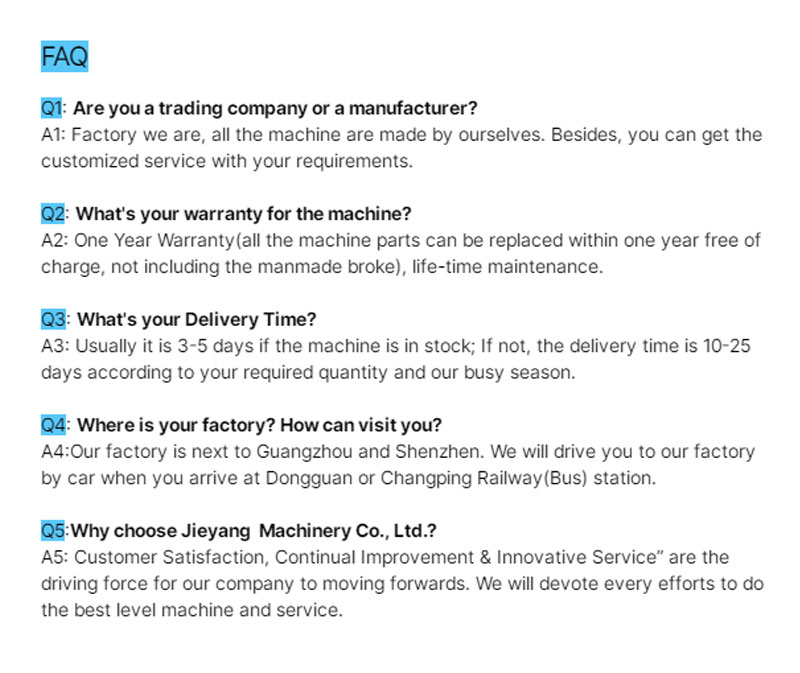

The machine is designed with operational convenience in mind, featuring a layout that simplifies mold installation, material maintenance, and production monitoring. Operators can quickly access the mold area, adjust settings, or manage cleaning tasks without disrupting the overall workflow.

Its optimized working height and operational clearance create a more user-friendly environment for both manual and automated production lines. This contributes to reduced downtime and increased overall equipment efficiency.

Flexible Platform for Automation Upgrades

The JY-450ST is compatible with automation components such as:

robotic arms

automated insert feeders

sliding tables

rotary workstations

conveyor systems

This flexibility makes it a powerful platform for businesses transitioning from manual to semi-automatic or fully automatic injection molding operations. The production line can be expanded without replacing the core injection equipment, reducing long-term investment costs.

Designed for Multi-Material Versatility

The machine can handle a wide range of thermoplastic resins, making it suitable for multiple product categories and production requirements. Its stable temperature control and adjustable processing parameters allow the JY-450ST to adapt to different molding conditions, improving productivity and reducing material waste.

Industries that commonly benefit include:

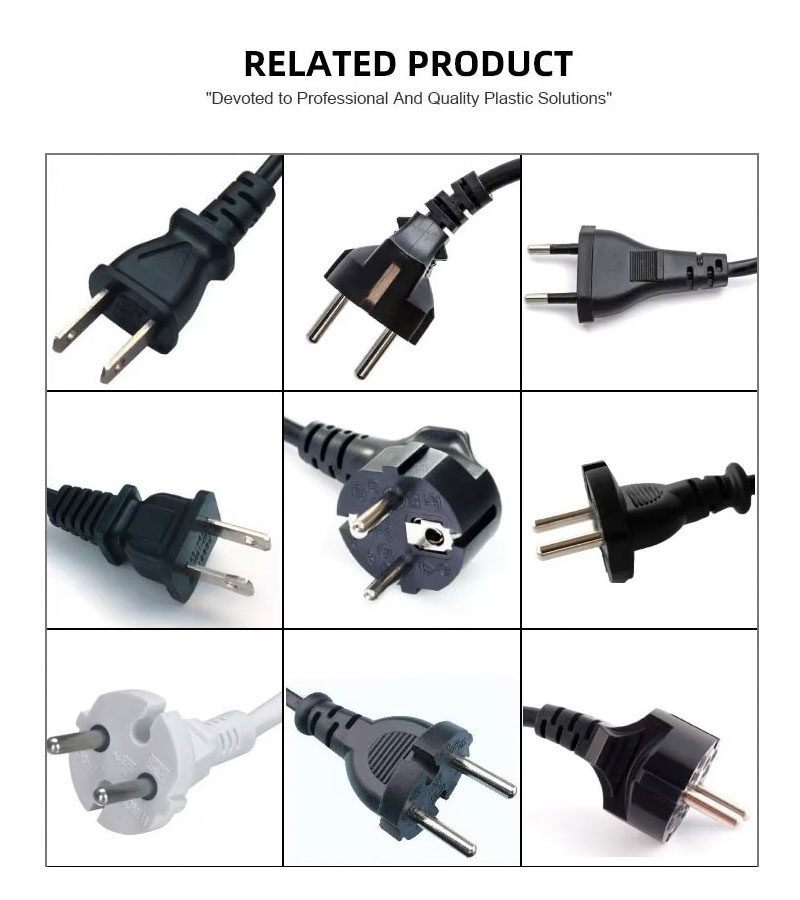

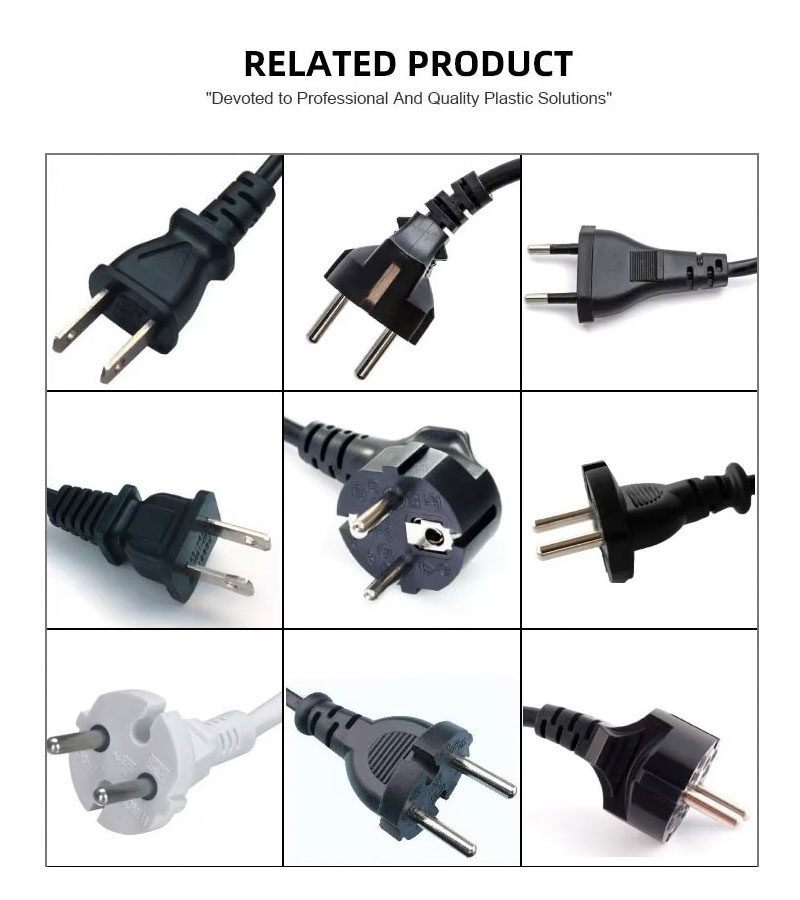

plug and connector manufacturing

household electrical appliances

automotive wiring systems

electronic device components

small precision plastic accessories

A Reliable Choice for High-Precision Plug Production

With its strong mechanical structure, flexible configuration, precise injection control, and compatibility with industrial automation, the JY-450ST is an ideal choice for plug molding manufacturers seeking long-term performance, stability, and quality.

It is built to support continuous, high-pressure manufacturing environments while maintaining consistent accuracy across every production cycle.