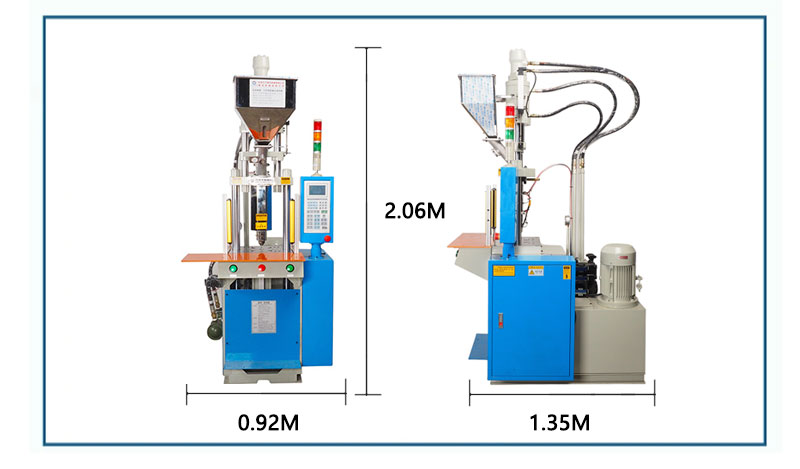

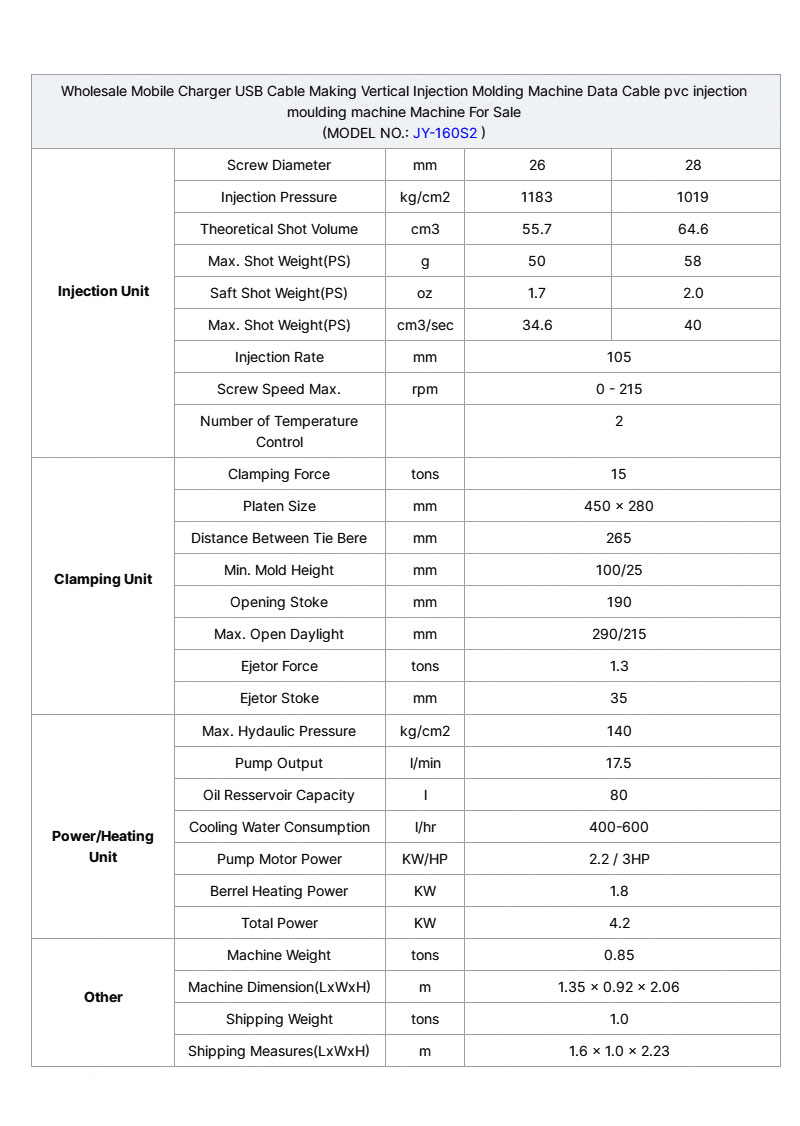

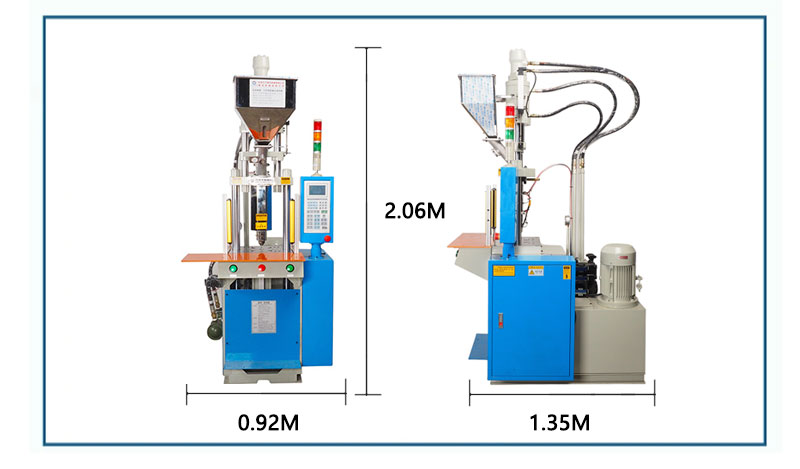

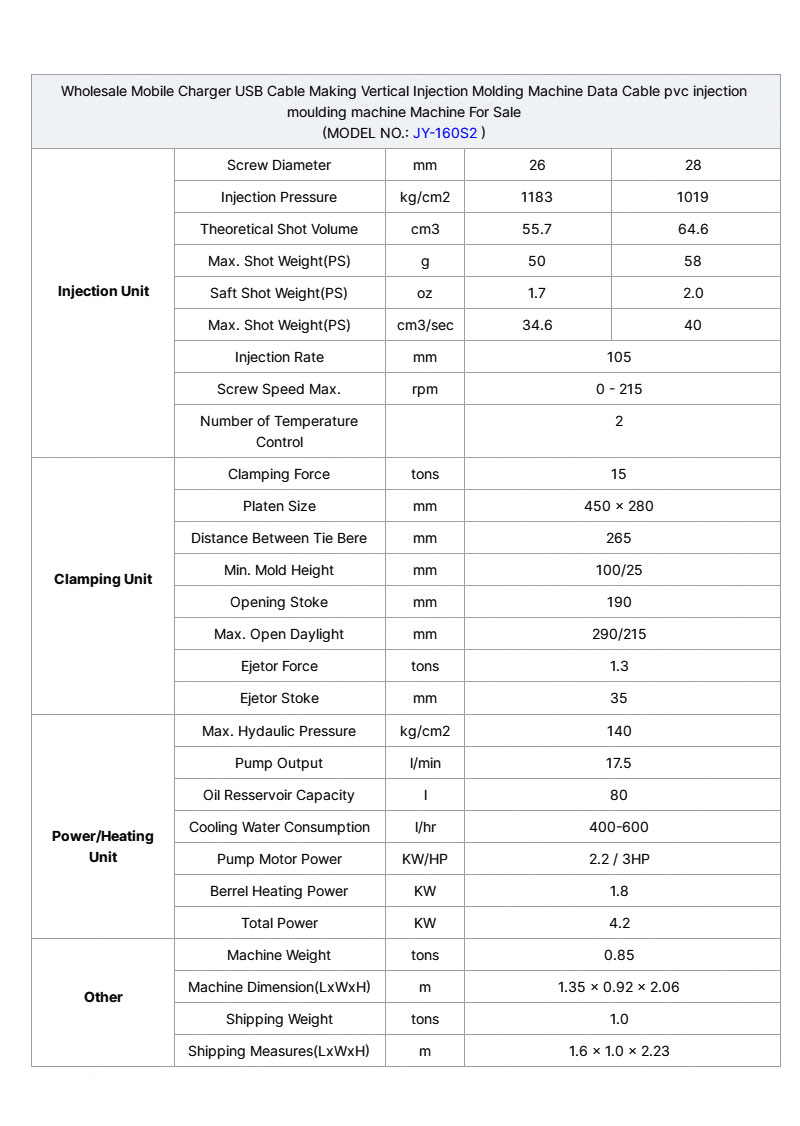

The JY-160S2 Standard Plastic Injection Machine is a versatile and reliable vertical injection molding solution designed for manufacturers requiring consistent performance, stable clamping, and high precision for insert molding applications. Engineered with a straight screw ejection system and multi-phase temperature control, this model is ideal for producing electronic components, hardware inserts, precision molded parts, and various plastic products requiring exceptional stability and repeatability.

Built with a fixed bottom mold and a movable top mold, the JY-160S2 provides wide compatibility for insert molding while ensuring operator safety and superior part quality.

Key Features & Technical Advantages

Straight Screw Ejected Assembly for Stable and Accurate Molding

The JY-160S2 is equipped with a straight screw ejection system, delivering consistent plasticizing performance, high injection accuracy, and excellent melt uniformity.

This mechanism ensures smooth material flow, making the machine suitable for producing small to medium-sized precision components.

Multi-Phase Temperature & Injection Control

The machine supports two-phase or three-phase temperature control, enabling precise processing of various thermoplastics.

Operators can independently adjust:

barrel temperature

injection speed

screw speed

back pressure

These settings provide excellent flexibility for materials such as ABS, PC, PP, PE, PVC, nylon, engineering plastics, and other specialty materials.

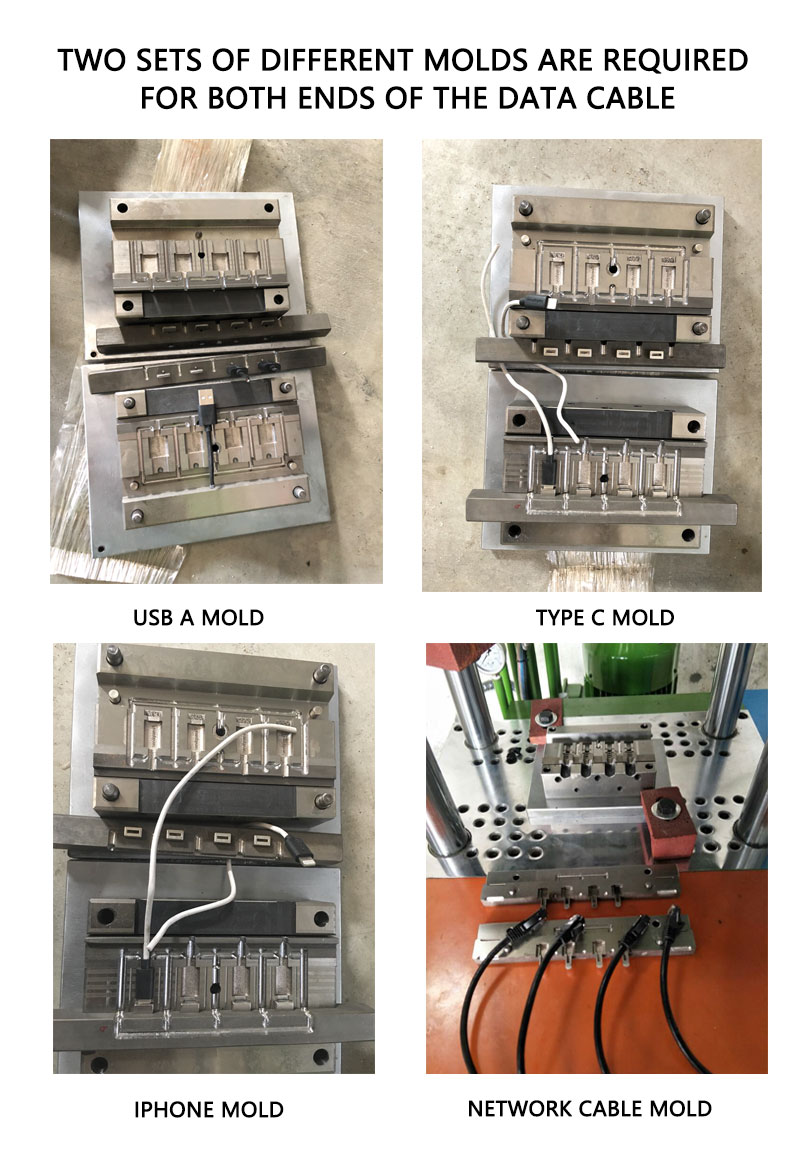

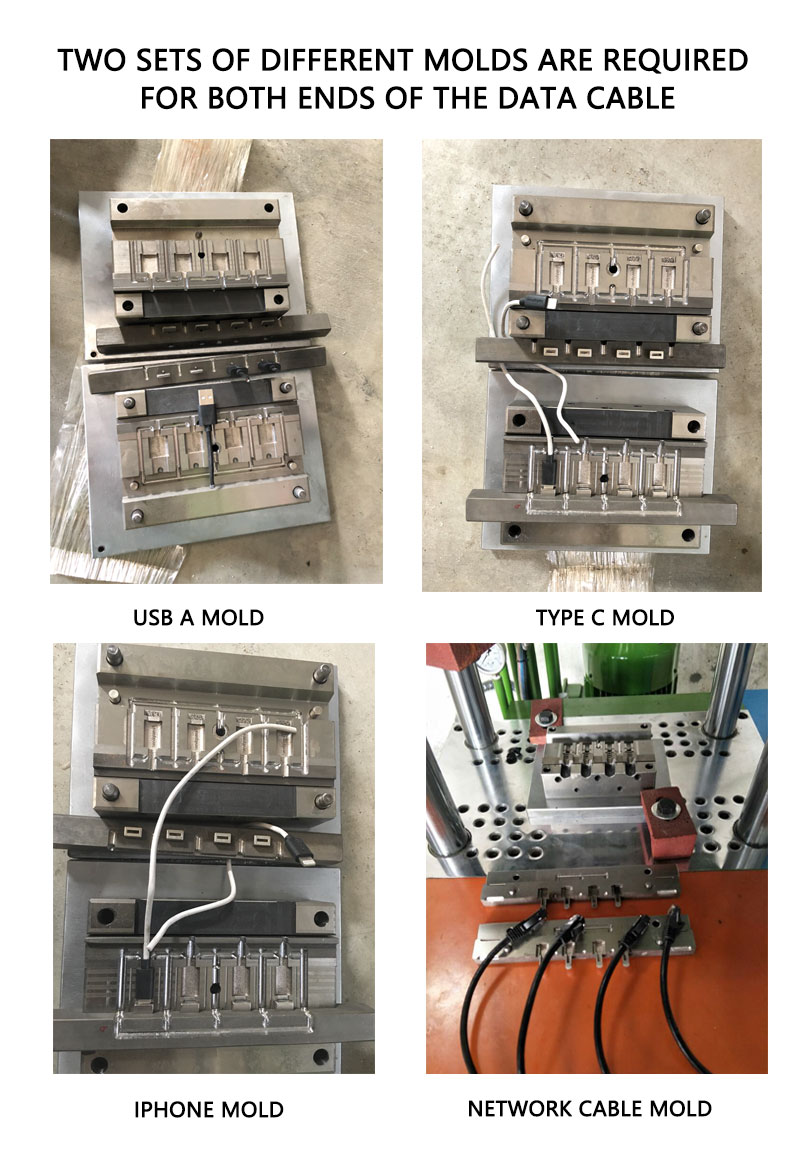

Ideal Structure for Insert Molding

Featuring a fixed bottom mold and a movable top mold, the JY-160S2 is structurally optimized for insert molding, manual part placement, and automated insert feeding.

This configuration ensures:

The machine also includes a product ejector system, making finished part removal easier and improving production efficiency.

Low-Pressure Mold Protection System

To ensure operator and mold safety, the machine integrates a low-pressure mold closing function.

Benefits include:

preventing mold damage caused by misalignment

reducing wear on mold components

improving mold lifetime

enhancing overall equipment safety

This is especially valuable for insert molding, where foreign objects or inserts may occasionally shift during placement.

Why Choose the JY-160S2?

Built for high-precision vertical injection molding

Excellent for insert molding and overmolding

Stable screw plasticizing and injection performance

Flexible temperature and injection parameter control

Safe low-pressure mold protection

Suitable for diverse thermoplastic materials

Easy integration with automated production systems

The JY-160S2 is a strong choice for manufacturers in electronics, consumer goods, electrical components, tools, medical plastic parts, and small precision product sectors.